An auto pallet changer (APC) is quickly becoming an essential upgrade for modern CNC machining environments. In today’s competitive manufacturing landscape, minimizing idle time and maximizing machine utilization are key drivers of profitability—and APCs offer a reliable solution to meet these goals.

This article explains what an auto pallet changer is, how it works, and how PARKSON’s automatic pallet changer solutions can help manufacturers significantly boost production efficiency and flexibility.

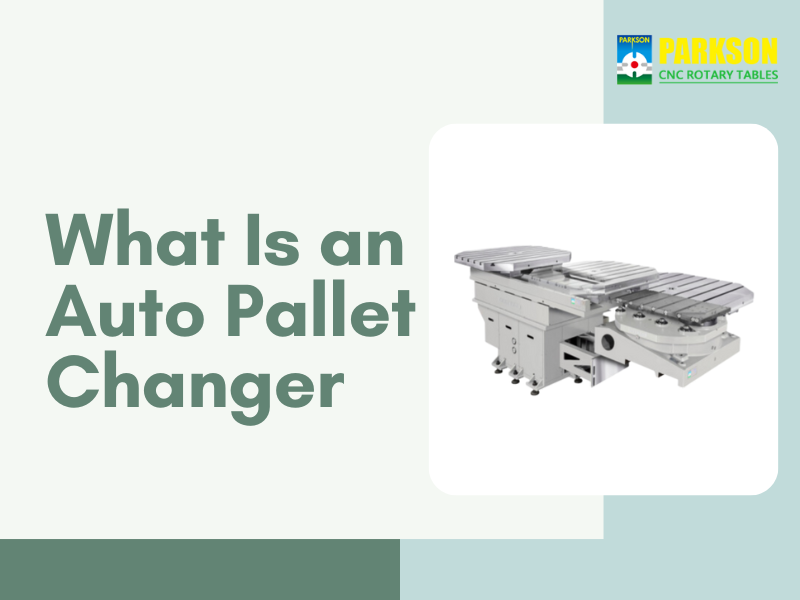

What Is an Auto Pallet Changer?

An auto pallet changer is a system that allows for the automatic exchange of pallets—each holding a workpiece—in CNC machining centers. While one pallet is being machined, another can be prepped outside the machine. Once the cycle is complete, the APC system swaps the pallets quickly and precisely, allowing for continuous operation with minimal interruption.

Unlike manual part loading, auto pallet changers support unattended machining, increase spindle uptime, and contribute to a more streamlined and automated production process.

How Does It Work?

Auto pallet changers typically operate in a dual-pallet configuration:

- Pallet A is inside the machine being machined.

- Pallet B is outside, where the operator can load a new workpiece.

- After machining, the system automatically swaps the pallets.

- The machine resumes cutting on Pallet B, while Pallet A is unloaded and reloaded.

This entire sequence happens without shutting down the machine, maximizing productivity.

PARKSON Auto Pallet Changer Solutions

PARKSON offers a complete lineup of automatic pallet changers designed to integrate seamlessly with both vertical and horizontal machining centers. Engineered for precision, durability, and flexibility, PARKSON's APC systems suit a wide range of production requirements.

Key Product Lines:

- Vertical APC Series

Designed for vertical machining centers, featuring servo motor or hydraulic gear transmission for fast, stable pallet exchange. Compact structure with excellent accessibility.

- Horizontal APC Series

Built for horizontal machines, offering robust construction and high-speed pallet rotation, suitable for heavy-duty cutting and large-part machining.

- APCP Series

A high-performance series with enhanced structural rigidity, air-blow cleaning, and precise clamping mechanisms—ideal for automated and smart manufacturing environments.

Each PARKSON APC model includes:

- Powerful air-blow system to clean positioning surfaces

- Hydraulic clamping with positioning pins for repeatable accuracy

- Fast exchange time to reduce machine idle periods

- Flexible design adaptable to diverse workpiece sizes and machine brands