APPLICATIONS

SOLUTIONS

3C high-tech industry, semiconductor parts

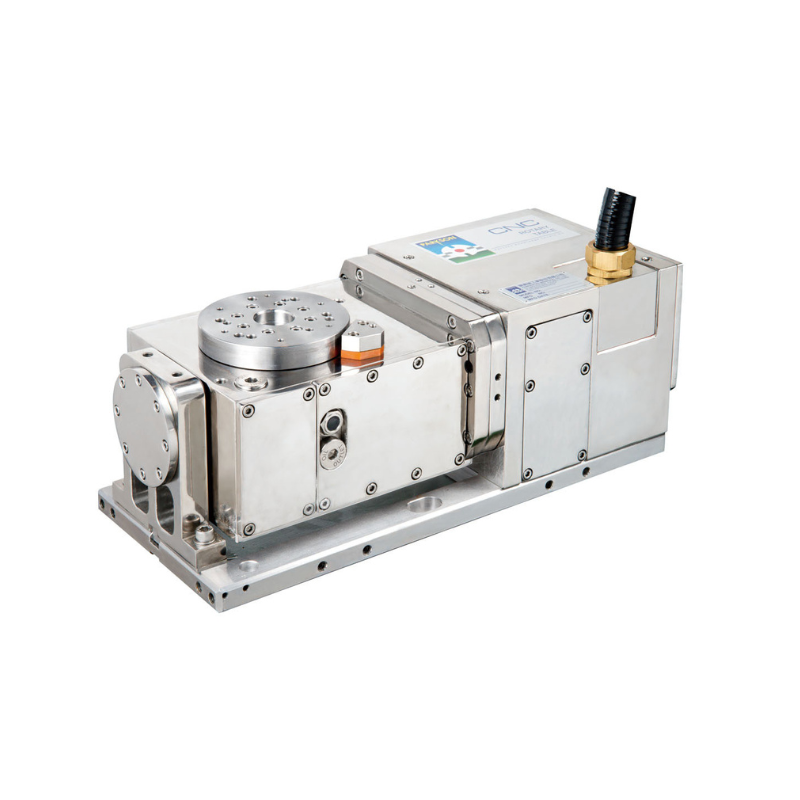

CNC rotary tables play a key role in the 3C industry and in semiconductor manufacturing. These industries require high precision and consistency of parts to ensure product performance and reliability. CNC rotary tables provide precise angular control and stable rotation, enabling precision machining of small, complex structures. In the manufacturing of 3C products, such as cell phones, tablet PCs and laptops, CNC rotary tables are used to process various precision parts, such as metal chassis, aluminum alloy frames and plastic components. The accuracy of these parts is directly related to the appearance and performance of the product.

CNC rotary tables also play a key role in semiconductor manufacturing. Semiconductor manufacturing requires a high degree of precision machining to create the tiny wafers and components. CNC rotary tables ensure high quality and reliability of semiconductor components by enabling extremely high precision and stability during the machining process. In wafer processing and packaging, CNC rotary tables are used to process wafers and packaging materials of various sizes and shapes, ensuring efficient and stable processes.

In addition, CNC rotary tables play an important role in the quality inspection and assembly stages. They provide precise positioning and stable rotation to ensure component inspection and assembly accuracy. In the quality inspection process, CNC rotary tables are used to inspect parts of various sizes and shapes to ensure that they meet specified tolerances. In the assembly process, CNC rotary table can precisely position the parts to ensure the assembly precision and consistency of the products.

CNC rotary tables also play a key role in semiconductor manufacturing. Semiconductor manufacturing requires a high degree of precision machining to create the tiny wafers and components. CNC rotary tables ensure high quality and reliability of semiconductor components by enabling extremely high precision and stability during the machining process. In wafer processing and packaging, CNC rotary tables are used to process wafers and packaging materials of various sizes and shapes, ensuring efficient and stable processes.

In addition, CNC rotary tables play an important role in the quality inspection and assembly stages. They provide precise positioning and stable rotation to ensure component inspection and assembly accuracy. In the quality inspection process, CNC rotary tables are used to inspect parts of various sizes and shapes to ensure that they meet specified tolerances. In the assembly process, CNC rotary table can precisely position the parts to ensure the assembly precision and consistency of the products.