APPLICATIONS

SOLUTIONS

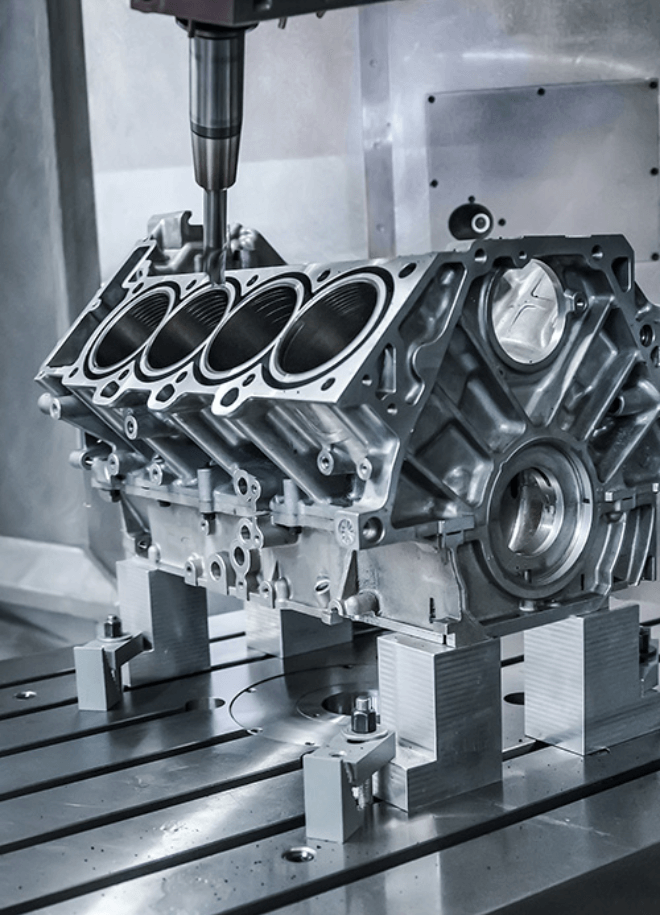

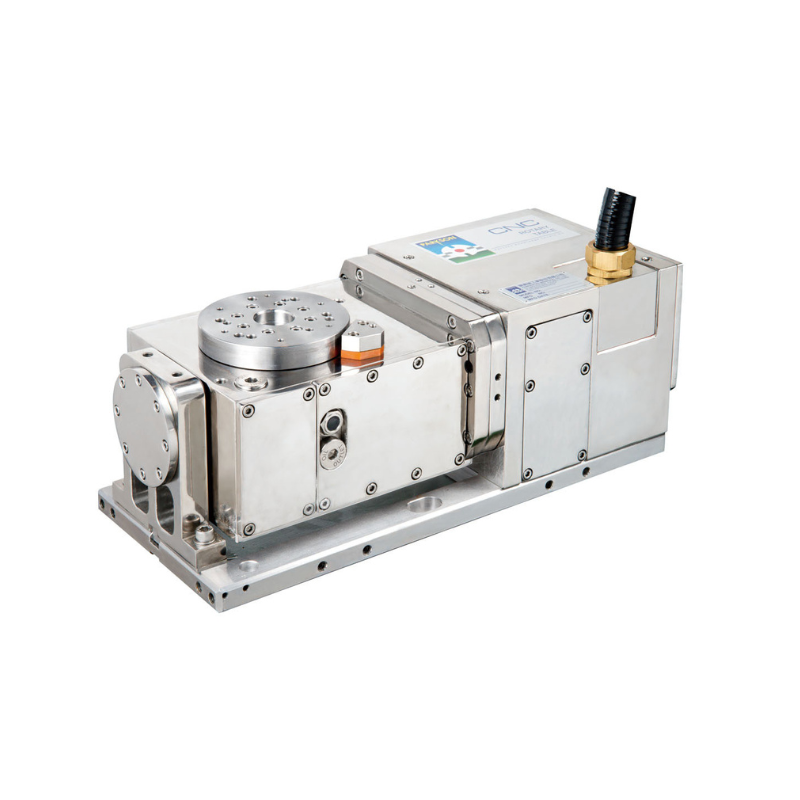

Machine Tool Parts Processing Industry

CNC rotary tables play a vital role in the machining of machine tool parts. The manufacture of machine tool parts requires high precision machining techniques to ensure the accuracy and performance of the final product. CNC rotary tables provide precise angular control and stable rotation, enabling precision machining of a wide range of complex geometric parts. These parts include gears, screws, bearings, connecting rods and other key components of tooling, and their manufacturing accuracy directly affects the machining efficiency and precision of the tooling machine.

CNC rotary tables have a wide range of applications in the machining of tooling machine parts. For example, in gear machining, machine tool parts need to be precisely machined at different angles and directions to ensure the accuracy and noise level of the gear. CNC rotary tables can realize the precise positioning and rotation of these parts to ensure the machining accuracy and consistency of each gear. Similarly, in the machining of screws and nuts, the CNC rotary table is able to realize the thread machining in different angles and directions to ensure the interchangeability and sealing of screws and nuts.

In addition, CNC rotary tables are also very important in the machining of tooling machine parts such as bearings and connecting rods. Bearings require high-precision machining of inner and outer rings and rolling elements to ensure smooth operation and long life of the bearings. The machining of connecting rods also requires highly precise positioning and rotation to ensure that the straightness and parallelism of the connecting rods meet the design requirements.

CNC rotary tables have a wide range of applications in the machining of tooling machine parts. For example, in gear machining, machine tool parts need to be precisely machined at different angles and directions to ensure the accuracy and noise level of the gear. CNC rotary tables can realize the precise positioning and rotation of these parts to ensure the machining accuracy and consistency of each gear. Similarly, in the machining of screws and nuts, the CNC rotary table is able to realize the thread machining in different angles and directions to ensure the interchangeability and sealing of screws and nuts.

In addition, CNC rotary tables are also very important in the machining of tooling machine parts such as bearings and connecting rods. Bearings require high-precision machining of inner and outer rings and rolling elements to ensure smooth operation and long life of the bearings. The machining of connecting rods also requires highly precise positioning and rotation to ensure that the straightness and parallelism of the connecting rods meet the design requirements.