APPLICATIONS

SOLUTIONS

Bicycle, electric vehicle, automobile, and ship parts processing industry

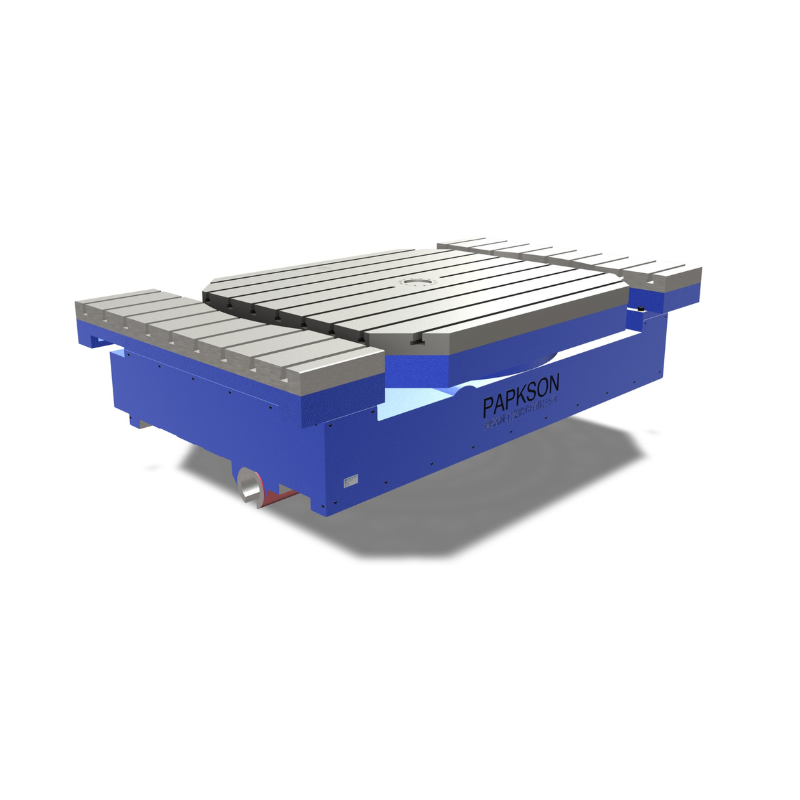

CNC rotary tables play a vital role in the machining of bicycle, electric vehicle, automobile and marine parts. These industries demand the highest levels of accuracy and consistency to ensure product performance and safety. CNC rotary tables provide precise angular control and stable rotation during the machining process, enabling precision manufacturing of complex geometries. Whether it's transmission system components for bicycles, motor components for electric vehicles, engine and transmission components for automobiles, or propulsion systems and structural components for ships, the manufacturing accuracy of these critical parts directly affects the overall product performance and life.

CNC rotary tables enable efficient multi-station machining by providing precise positioning and repositioning. This is especially important in the manufacture of parts that require multi-angle and multi-directional machining. For example, the cylinders and pistons of an automobile engine need to be precisely machined at different angles, and the CNC rotary table ensures the accuracy of each machining position, thus improving the efficiency and power output of the engine. Similarly, the rotor and stator components of an electric vehicle motor require extremely high machining accuracy to ensure the motor's operational efficiency and longevity.

CNC rotary tables are also widely used in bicycle and shipbuilding. High-end transmission systems in bicycles require lightweight and high-strength components, and CNC rotary tables can realize the precision machining of these components to enhance the performance and durability of the entire vehicle. The propulsion system and structural components of ships need to maintain efficient operation in harsh marine environments, and the machining accuracy of these components directly affects the navigational performance and safety of ships. The CNC rotary table ensures the quality and reliability of these parts through precise machining control.

CNC rotary tables enable efficient multi-station machining by providing precise positioning and repositioning. This is especially important in the manufacture of parts that require multi-angle and multi-directional machining. For example, the cylinders and pistons of an automobile engine need to be precisely machined at different angles, and the CNC rotary table ensures the accuracy of each machining position, thus improving the efficiency and power output of the engine. Similarly, the rotor and stator components of an electric vehicle motor require extremely high machining accuracy to ensure the motor's operational efficiency and longevity.

CNC rotary tables are also widely used in bicycle and shipbuilding. High-end transmission systems in bicycles require lightweight and high-strength components, and CNC rotary tables can realize the precision machining of these components to enhance the performance and durability of the entire vehicle. The propulsion system and structural components of ships need to maintain efficient operation in harsh marine environments, and the machining accuracy of these components directly affects the navigational performance and safety of ships. The CNC rotary table ensures the quality and reliability of these parts through precise machining control.