Rotary tables are essential components in CNC machining, allowing for precise positioning and multi-axis movement. Among the various types, horizontal rotary tables are widely used for their versatility and efficiency in machining complex parts. In this article, we’ll explain what a horizontal rotary table is, its key features, explore the different types of rotary tables, and provide tips on choosing the right one for your needs.

What is a Horizontal Rotary Table?

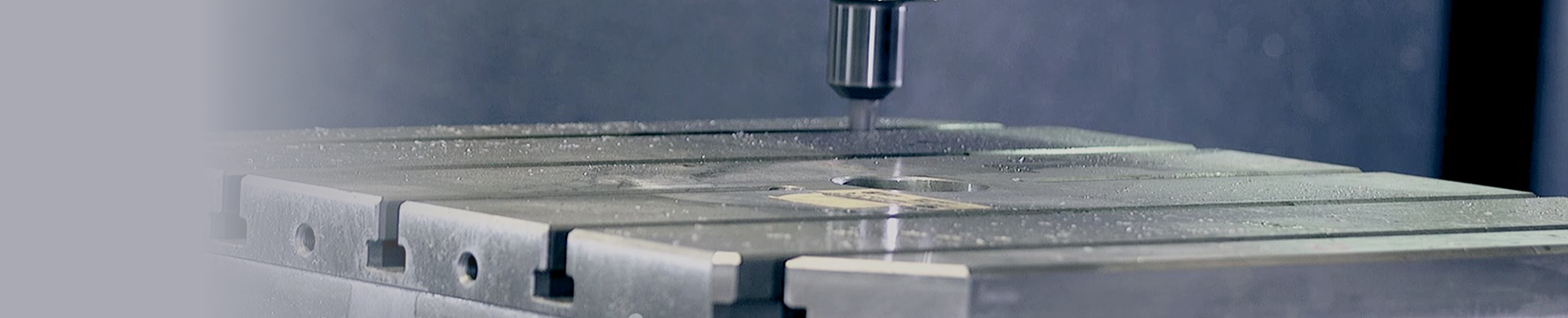

A horizontal rotary table is a machining accessory used in CNC milling and drilling operations. Positioned horizontally on the machine bed, it allows the workpiece to rotate around a fixed axis, enabling precise cutting at different angles. Horizontal rotary tables are particularly suitable for machining flat surfaces, circular cuts, and components requiring multi-side operations.

Key features of a horizontal rotary table include:

- High Precision: Provides accurate positioning for intricate machining tasks.

- Versatility: Accommodates various machining operations such as drilling, milling, and tapping.

- Enhanced Efficiency: Reduces the need for multiple setups by allowing continuous rotation of the workpiece.

Applications of Horizontal Rotary Tables

Horizontal rotary tables are used across industries for tasks requiring precision and efficiency, including:

- Aerospace: Machining turbine blades and engine components.

- Automotive: Manufacturing gears, shafts, and precision components.

- Medical Devices: Producing complex surgical instruments and implants.

- Energy: Creating components for wind turbines and other renewable energy systems.

Types of Rotary Tables

Rotary tables come in several designs, each catering to specific machining needs. Below are the main types:

1. Horizontal Rotary Tables

Mounted horizontally, these tables are ideal for machining flat surfaces or round parts. Their stable setup makes them perfect for heavy-duty machining tasks.

2. Vertical Rotary Tables

Mounted vertically, these tables are used for operations requiring access to the side of the workpiece. They are often employed for machining cylindrical parts or achieving angled cuts.

3. Tilting Rotary Tables

Combining the capabilities of horizontal and vertical tables, tilting rotary tables can be adjusted at various angles. They are ideal for multi-axis machining and complex geometries, such as impellers and turbine blades.

For more insights, check out our article on CNC Tilting Rotary Tables: Maximize Precision and Flexibility.

4. Cradle-Type Rotary Tables

A subtype of tilting rotary tables, cradle-type designs provide greater stability for large or heavy workpieces. They are commonly used in industries requiring precision for intricate, multi-surface machining.

5. Embedded-Type Rotary Tables

Integrated directly into the machine tool, these rotary tables save space and offer enhanced rigidity. They are perfect for high-speed and high-precision applications.

How to Choose the Right Rotary Table

Selecting the right rotary table depends on your machining needs and operational requirements. Consider these key factors when making your decision:

1. Application Requirements

Identify your machining tasks. Horizontal rotary tables are ideal for flat surfaces, while tilting or vertical tables are better for multi-angle cuts or cylindrical parts.

2. Load Capacity

Ensure the rotary table can handle the weight of your workpiece without compromising stability. Overloading a table may reduce accuracy and increase wear and tear.

3. Precision and Repeatability

Look for rotary tables with tight tolerance specifications and high repeatability to ensure consistent accuracy for high-precision machining.

4. Table Size and Compatibility

The rotary table should fit your machine tool and accommodate your workpiece size. Check compatibility with your CNC system to ensure seamless integration.

5. Ease of Operation

Features such as user-friendly controls and low-maintenance designs can improve operational efficiency and reduce downtime.

6. Durability and Build Quality

Invest in a rotary table made with high-quality materials and advanced engineering to ensure long-term reliability and performance.

7. Customizable Features

Depending on your requirements, consider tables with adjustable settings, such as tilt angles or additional axes, for greater versatility.

Why Choose PARKSON's Rotary Tables?

PARKSON offers a comprehensive range of rotary tables designed for precision, reliability, and versatility. Our horizontal rotary tables (B-axis) enable equal, unequal, or continuous rotary machining, making them ideal for diverse applications. When paired with accessories like manual tailstocks, rotary tailstocks, or center plates, these tables can expand the machining range, offering greater flexibility to meet varying processing needs.

Built with advanced engineering, PARKSON's rotary tables provide smooth operation, high load capacity, and seamless integration with CNC systems. Whether you require a standard solution or a customized design, PARKSON ensures that every table delivers exceptional performance for your machining tasks.

Conclusion

Horizontal rotary tables are indispensable for achieving precision and efficiency in CNC machining. By understanding the different types of rotary tables and considering the factors for selection, manufacturers can choose the right rotary table to optimize their production processes. PARKSON's rotary tables combine quality, durability, and innovation, making them an excellent choice for industries requiring high-precision machining.

Contact PARKSON today to explore our full range of rotary tables and discover how we can enhance your machining capabilities.